BENCH 0020-312

0020-312

TECHNICAL DESCRIPTION

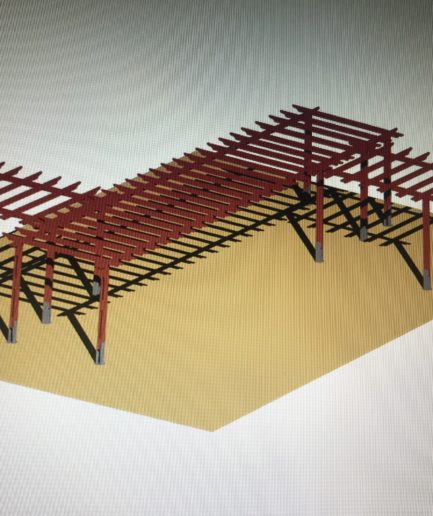

WOODEN BANK WITH SPEAKER

The wooden tablecloth with cover has overall dimensions:

200 cm wide, 200 cm long and 280 cm high

It consists of a table with two benches and a cover.

The table consists of four (4) woods 20×4,5 cm in length and 180 cm in length which are supported by two (2) woods 15×4,5×52 cm with the help of four (4) rails, two on each leg.

Each bench consists of three (3) 10×4,5 cm and 180 cm long woods, which are supported by two (2) woods with the help of four (4) planks, two on each leg.

The whole construction is based on two (2) 9×9 cm and 160 cm long woods.

The cover consists of two vertical columns 9X9 cm wide and 280 cm high, which support the upper part, which is made of 2×14 cm cross-section. The roof frame is made of composite timber of 6.5×4 cm on which the robot is screwed with wood screws. 6.5x4cm cross-section brackets are mounted for the best support of the roof, both ends of which are attached to the roof frame and there is contact with the central pillar.

The wood used is manufactured with a special joint (wood glue) in various sections depending on its intended use.

COMPOSITE wood is 40% stronger than whole wood. It has a strength of 360 kp / m2 and a specific weight of about 470 kg / m3.

It contains about 12% moisture

It has thermal conductivity s = 0.10 Kcal / Mho and sound insulation 3.5 times greater than concrete or brick of equal thickness.

It has antimagnetic properties and is a poor conductor of electricity

It is resistant to fire and is classified in categories F30 and F60 (by DIN 4120) according to its cross-section.

When the outer part of the cross-section burns, its interior protects and retains its durability.

It is processed just like commercial wood

It retains its shape and distorts or creates minimal fractures

Annual wood rings are usually perpendicular to the long side of the cross-section with a significant increase in the mechanical strength of this surface, if applied to floors.

The wood is deeply impregnated with vacuum – pressure – vacuum so that it is not affected by rot and insects.

METALLIC ELEMENTS

The metallic elements used for the manufacture of equipment (screws, joints, etc.) made of heat-galvanized steel (with zinc) or electro-galvanized where the surface preparation has been preceded by sandblasting. The dimensions and cross-sections of the metallic elements are sufficient to accommodate (with an appropriate safety factor) the loads for which they have been designed to withstand corrosion and adverse weather conditions.

PAINTS

The varnishes and colors that protect the wooden parts are specially designed for the climate of our country (temperature changes, open or closed areas etc.) are absolutely harmless to the users (they do not contain lead and other heavy metals) and give great resistance to our constructions.