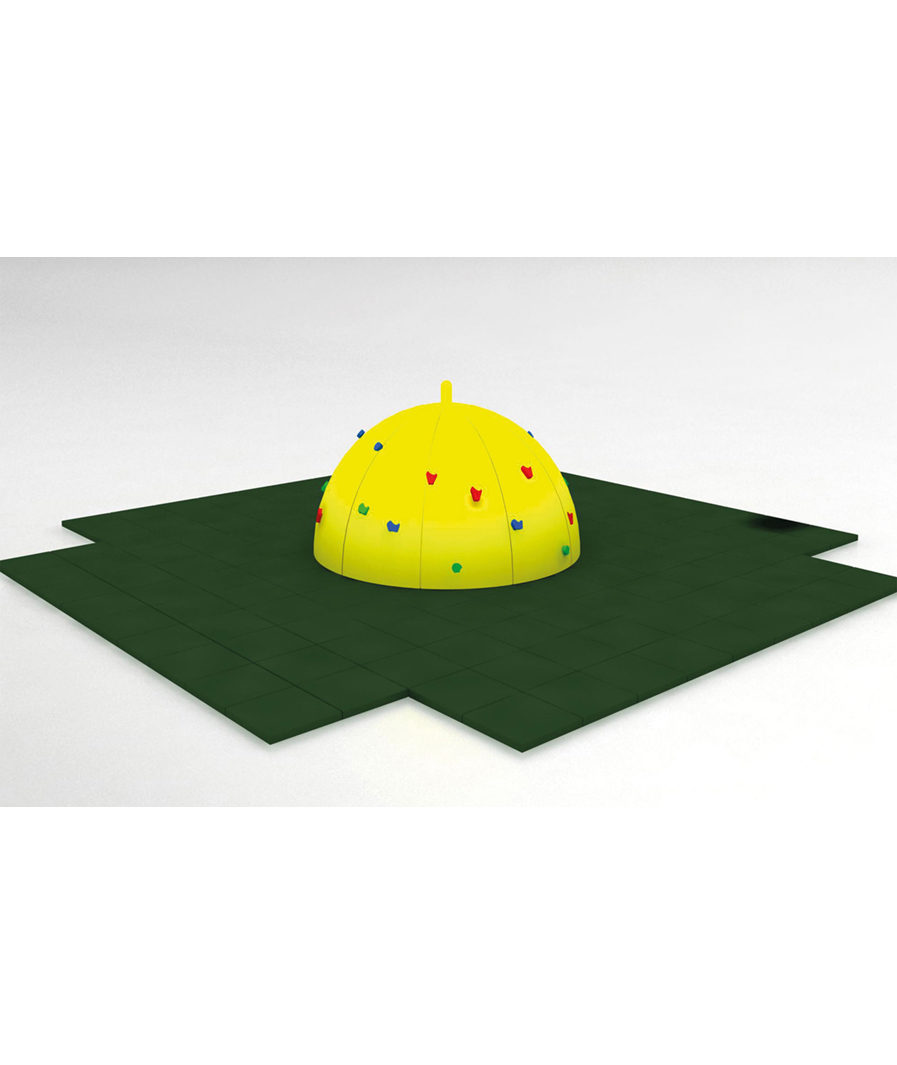

CLIMBING FRAME 10-05-33

The instrument consists of the outer lining (3 mm thick extruded sheet metal) and the inner frame (galvanized sheets with hot diagonal cross section F 70). The frame consists of 12 arcs of radius 120 cm which are joined at three points. : at the base, in the middle of the bow and at the top. The outer lining is electro-plated on them. On the lining there are climbing aids with the first starting at 40 cm from ground level and continuing at equal intervals.

BACKPACK BASES

The mounting bases consist of two galvanized metal plates and then painted with electrostatic paint, approximately 80×4 cm. At the bottom there is a metal gasket to hold them in the concrete pit.

PLASTIC INFORMATION

The plastic components required to manufacture the equipment are highly resistant to UV radiation and adverse weather conditions. Preferred are recyclable materials such as polyethylene (PE) or polypropylene (PP). Specifically all screws protruding from the equipment over 5 mm are covered with polypropylene (PP) plastic plugs. They are also safe for the safety and health of children.

METALLIC ELEMENTS

The metallic elements used in the manufacture of the equipment (screws, connectors, etc.) are made of metals either thermo-galvanized or electro-galvanized, where the surface preparation has been preceded by sandblasting or stainless steel. The dimensions and cross-sections of the metallic elements are sufficient to accommodate (with an appropriate safety factor) the loads for which they have been designed to withstand corrosion and adverse weather conditions. Painting of all metallic elements is done by the method of electrostatic painting

PAINTS

For their anticorrosive protection, the metal parts are processed to release them, followed by a coating of polyzinc (zinc) and then electrostatic, two-layer polyester powder coating.

PACKING

The following procedure is used for fixing the equipment:

At this point where the column is to be placed, an 80 cm deep pit is opened. about 60cm in diameter. Then, once the column is inserted, the pit is filled with frusto-concreted concrete until it reaches 10 cm. from the ground surface, where it is covered with soil.

Only ground irons, which hold each column at a distance of about 10 cm from the ground, are prevented on the ground in order to prevent the wood from corroding the soil moisture.

All production work processes for the processing of raw materials are carried out according to:

- EN 1176 standards 1-6,

- ISO 9001: 2015 quality system

- The ISO 14001: 2015 environmental management system