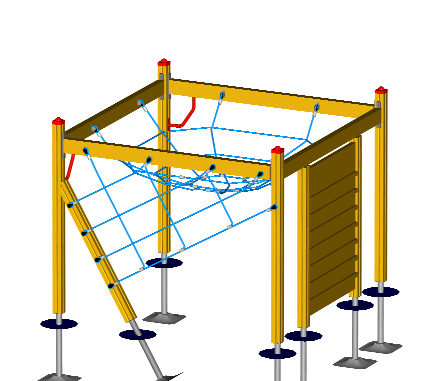

CLIMBING FRAME 0010-273

0010-273

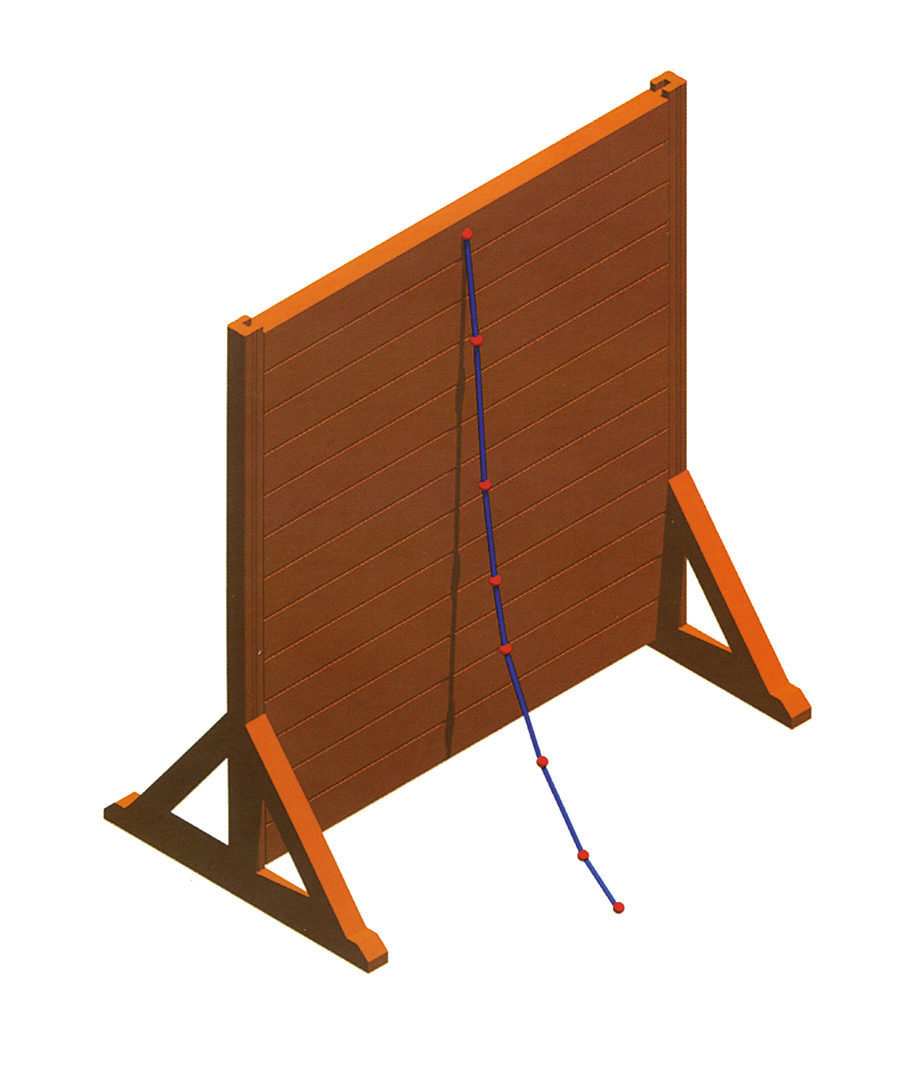

The rope climb has a total dimension of 120x200x220 cm. It consists of two wooden columns 9X9 cm in height and 211 cm high. These columns are torn in height and have 13 timber cross sections 9×15 cm and 191 cm long. There is a 9x9cm and 120cm cross-section timber and two 9x9cm diagonal timbers which support the construction. From the top and center of the instrument begins the climbing rope 250 cm long. All wooden parts are of composite Swedish pine timber, in accordance with EN 351.

The wooden parts are properly treated (rubbing, grinding, stocking) and are coated with two layers of water-soluble paint and one layer of protective wax.

TIMBER

The wood used is composite non-stick Swedish pine timber, in accordance with EN 351. It is manufactured with special compound (welding of wood) in different sections depending on the intended use.

COMPOSITE wood is 40% stronger than whole wood. It has a strength of 360 kp / m2 and a specific weight of about 480 kg / m3.

- Contains about 15% moisture

- Contains minimal juices (resin) compared to other pine family trees in other countries (weather in northern Sweden up to -25 ° C)

- Has thermal conductivity s = 0.10 Kcal / Mho and sound insulation 3.5 times greater than concrete or brick of equal thickness.

- Has antimagnetic properties and is a poor conductor of electricity

- Resistant to fire and classified in categories F30 and F60 (by DIN 4120) according to its cross-section.

- When the outer part of the cross-section burns, its interior protects and retains its durability.

- It is processed just like commercial wood

- Maintains its shape and distorts or creates minimal fractures

- Annual wood rings are usually perpendicular to the long side of the cross-section with a significant increase in the mechanical strength of this surface when applied to floors.

All corners of the wood are planed with a radius of about 5 mm.

PLASTIC INFORMATION

The plastic components required to manufacture the equipment are highly resistant to UV radiation and adverse weather conditions. Preferred are recyclable materials such as polyethylene (PE) or polypropylene (PP). Specifically all screws protruding from the equipment over 5 mm are covered with polypropylene (PP) plastic plugs. They are also safe for the safety and health of children.

METALLIC ELEMENTS

The metallic elements used in the manufacture of the equipment (screws, joints, etc.) are made of metals either thermo-galvanized or electro-galvanized, where the surface preparation has been preceded by sandblasting or stainless steel. The dimensions and cross-sections of the metallic elements are sufficient to accommodate (with an appropriate safety factor) the loads for which they have been designed to withstand corrosion and adverse weather conditions.

PAINTS

The varnishes and the colors that protect the wooden parts are specially designed for the climate of our country (temperature changes, open or closed areas etc.) are absolutely harmless to the users (they do not contain lead, chromium, cadmium and other heavy metals). ) and give great durability to our constructions.

All production work processes for the processing of raw materials are carried out according to:

- EN 1176 standards 1-6,

- ISO 9001: 2015 quality system

- The ISO 14001: 2015 environmental management system