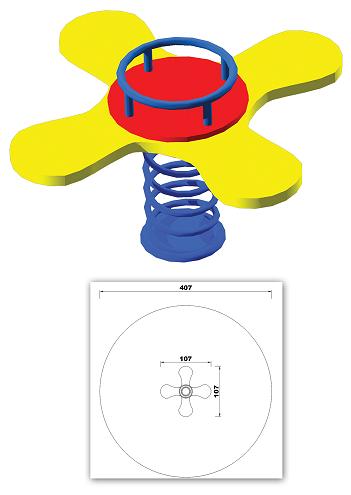

SEESAW 0010-237

The four-seater infant seesaw is 107×107 cm and about 50 cm high. The main element that forms the trunk – base for the climb of children is made of oval cross shaped birch plywood with curved edges 35 mm thick.

It has in the center of a birch plywood colored Ø 395 mm thick 20 mm circular and used as a base.

It has a circular plate Ø 20 mm in the center of it, mounted on four straps Ø 315 mm screwed with electro-galvanized screws and nuts. The lower center section has a safety spring Ø 25 mm with upper and lower spacers.

The lower part of the oscillation spring is pressed or mounted to the ground (ground or sub-mounting).

COLORED PLYWOOD BIRCH

The plywood elements required for our constructions are about 20 mm thick and are made of 1.5 mm thick timber sheets bonded to each other by pressure-sealing using non-toxic phenolic base resins. They are painted with water-soluble paints to which no seals, thinners or paints containing lead, chromium, cadmium or other heavy metals have been attached. The colors are also very resistant to adverse weather conditions.

The above plywood sheets are in accordance with EN 314-2. The quality of the plywood is such that no further processing is required before painting, such as, for example, stocking, and reliefs and themes can be engraved.

PLASTIC INFORMATION

The plastic components required to manufacture the equipment are highly resistant to UV radiation and adverse weather conditions. Preferred are recyclable materials such as polyethylene (PE) or polypropylene (PP). Specifically all screws protruding from the equipment over 5 mm are covered with polypropylene (PP) plastic plugs. They are also safe for the safety and health of children.

METALLIC ELEMENTS

The metallic elements used in the manufacture of the equipment (screws, joints, etc.) are made of metals either thermo-galvanized or electro-galvanized, where the surface preparation has been preceded by sandblasting or stainless steel. The dimensions and cross-sections of the metallic elements are sufficient to receive (with an appropriate safety factor) the loads for which they have been designed to withstand corrosion and adverse weather conditions.

PAINTS

The varnishes and colors that protect the wooden parts are specially designed for the climate of our country (temperature changes, open or closed areas etc.) are completely harmless to the users (they do not contain lead, chromium, cadmium and other heavy metals) and give great strength to our constructions.

For their anticorrosive protection, the metal parts of the mill are processed for polishing, followed by a coating of polyzinc (zinc) followed by a two-layer electrostatic powder coating.

PACKING

The following procedure is used for fixing the equipment:

At this point where the column is to be placed, an 80 cm deep pit is opened about 60cm in diameter. Then, after the column is inserted, the pit is filled with frusto-concreted concrete until it reaches 10 cm. from the ground surface, where it is covered with soil.

Only ground irons, which hold each column at a distance of about 10 cm from the ground, are prevented on the ground in order to prevent the wood from being corroded by soil moisture.

All production work processes for the processing of raw materials are carried out according to:

EN 1176 standards 1-6,

The ISO 9001: 2015 quality system

The ISO 14001: 2015 Environmental Management System