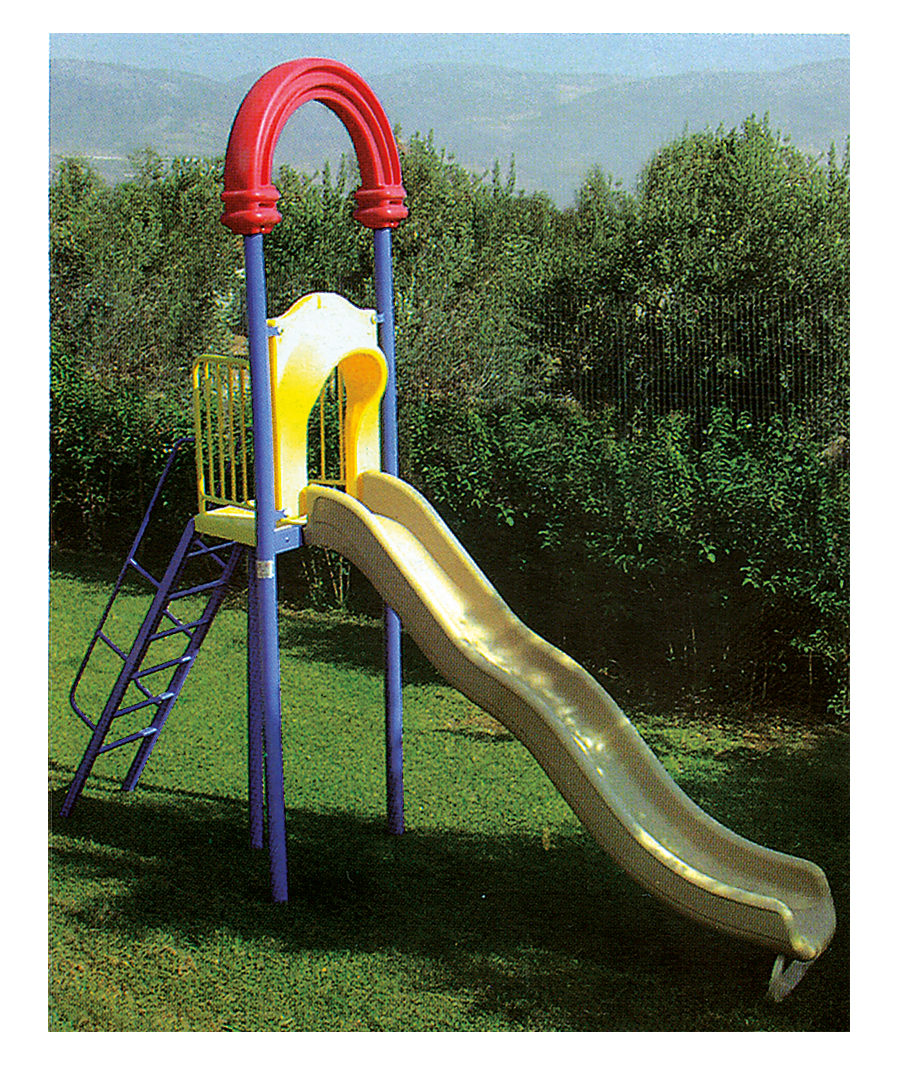

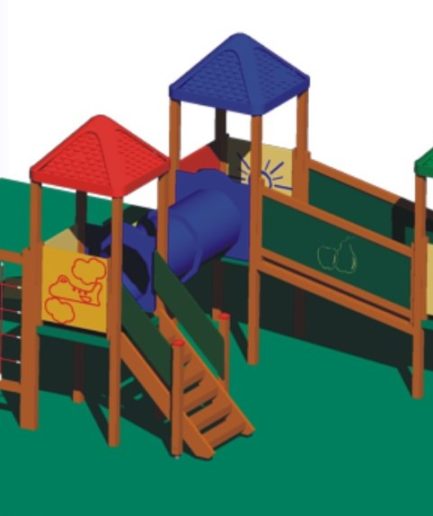

STEEL STRUCTURE 0010-269Α

0010-269A

TECHNICAL DESCRIPTION

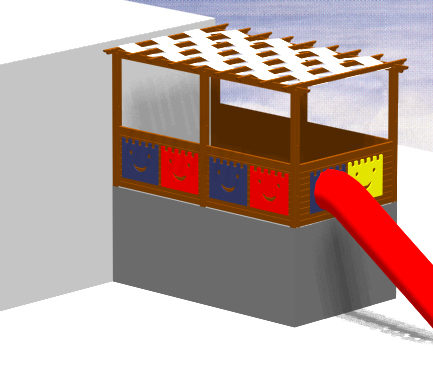

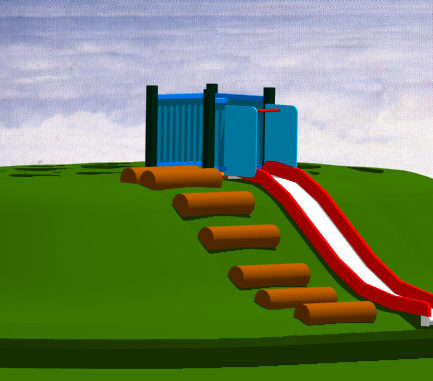

SLIDE WITH LOFT

The slide consists of a staircase climbing staircase, two support pillars and a cathode and a central attic support pillar. The two pillars supporting the loft are of hot rolled laminate Ø3 ″ and are 225 cm high while the central pillar supporting the loft is 122 cm high.

CLIMBING LADDER HEIGHT 122 EC.

The climbing ladder consists of 4 steps of 6x2cm and 52cm long oval tubes, of 4x6cm cross-section stairs, handrail and bars made of hot rolled laminate Ø ¾ “.

The loft handrails are “P” shaped with rounded corners and are made of hot rolled laminate Ø1 “. In the meantime there are hot-rolled laminated railings Ø ½ ”.

STRAIGHT CORRUGATED SLIDE 122 CM.

The straight corrugated slide is approximately 122 cm high and 235 cm in height from the loft.

It is manufactured by the rotary extraction method. It consists of linear low density polyethylene and with the addition of materials that provide protection from UV radiation and against static electricity.

Each color, which is non-toxic, is applied by rotary extraction of the mold. It is a one-piece and mounted with a one-piece Hood cover of the same material, for protection against falls

These materials are disciplined by:

ASTM – D – 790 (Flex Modulus – Flexible Components)

ASTM – D – 638 (Tensile Strength)

ASTM -D- 648 (Heat Distortion Temperature- Heated Distortion)

ARM – STD (Low Temperature Impact – low temperature impact effect)

The side walls should have a diameter of at least 5 cm. Exceptions should be mentioned.

ASTM = the American Society for Testing and Materials, the American Materials Testing and Testing Service.

ARCH

The arch has a hole-to-hole dimension of 1015 mm.

It is manufactured by the molding rotary extraction method. It is formed of linear low density polyethylene with UV stabilizers and has been treated with ‘High Level Antistatic’ (static electricity neutralization treatment).

Each color, which is non-toxic, is applied by rotary extraction of the mold. It’s a one-piece piece.

These materials are disciplined by:

ASTM – D – 790 (Flex Modulus – Flexible Components)

ASTM – D – 638 (Tensile Strength)

ASTM – D – 648 (Heat Distortion Temperature – Heated Distortion)

ARM – STD (Low Temperature Impact – low temperature impact effect)

ASTM = the American Society for Testing and Materials, the American Materials Testing and Testing Service.

PLASTIC INFORMATION

The plastic components required to manufacture the equipment are highly resistant to UV radiation and adverse weather conditions. Preferred are recyclable materials such as polyethylene (PE) or polypropylene (PP). Specifically all screws protruding from the equipment over 5 mm are covered with polypropylene (PP) plastic plugs. They are also safe for the safety and health of children.

METALLIC ELEMENTS

The metallic elements used in the manufacture of the equipment (screws, joints, etc.) are made of metals either thermo-galvanized or electro-galvanized, where the surface preparation has been preceded by sandblasting or stainless steel. The dimensions and cross-sections of the metallic elements are sufficient to accommodate (with an appropriate safety factor) the loads for which they have been designed to withstand corrosion and adverse weather conditions.

PAINTS

For their anticorrosive protection, the metal parts are processed to release them, followed by a coating of polyzinc (zinc) and then electrostatic, two-layer polyester powder coating.

PACKING

The following procedure is used for fixing the equipment:

At this point where the column is to be placed, an 80 cm deep pit is opened. about 60cm in diameter. Then, once the column is inserted, the pit is filled with fractured cone-shaped concrete until it reaches 10 cm from the ground surface, where it is covered with soil.

Only grounding irons, which hold each column at a distance of about 10 cm from the ground, are prevented on the ground in order to prevent the wood from being corroded by soil moisture.

All production work processes for the processing of raw materials are carried out according to:

EN 1176 standards 1-6,

The ISO 9001: 2015 quality system

The ISO 14001: 2015 Environmental Management System