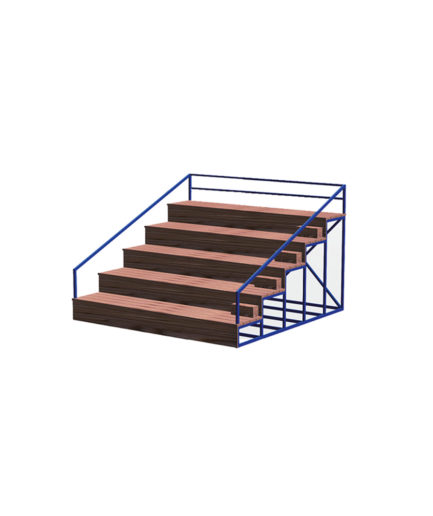

BASKETBALL STAND 0030-404

0030-404

The variable height mobile basket has the ability to vary the height of its hoop from 275 cm to 305 cm.

Consists of :

The base

The beams

The shock absorber

The board

The hoop

The counterweight

The base of the basket is made of a cross-section 60×40 mm and 3 mm thick. It is a square frame 150×90 cm. which is filled with sand to prevent the basketball from oscillating. The base also includes a ”P-shaped tube handle 90×30 cm. In the center of the base there is a 60×40-by-83-cm-long bushing that attaches to the basket shock absorber.

On one side of the base having a length of 90 cm, two connectors of 12 cm height start and the distance between them is 60 cm.

They are connected to the two beams of the basket, which are similarly made of a 60×40 mm cross-section, 3 mm thick and have a height of 300 cm. At the center of this tube is another galvanized tube.

Between the two beams and at a height of 66 cm from the top there is a 30X30 caliper and just below it, protrude from the two beams two 3/4 σω tubes.

The dashboard is made of a 50X30 corner and has a dimension of 90X120 cm. A second smaller metal frame is made at the center of the metal frame and at equal distances from the vertical sides, 30 cm from the bottom of the frame. The plexi glass panel is dimensioned 90X120 cm and 12 mm thick it is mounted on the metal corners with milling screws and an elastic membrane is inserted between it and the metal corners to absorb the vibrations.

The hoop is made of iron rod F 20 with an inner net diameter of 45 cm and is mounted on the mounting base of the panel with screws, which pass through special brass cylindrical sockets of the panel and screw in the plates joining the inner small frame with the perimeter frame. labeling. At the bottom of the rim there are 12 hooks to support the net, which are designed to prevent accidents.

METALLIC ELEMENTS

The metallic elements used in the manufacture of the equipment (screws, connectors, etc.) are made of metals either thermo-galvanized or electro-galvanized, where the surface preparation has been preceded by sandblasting or stainless steel. The dimensions and cross-sections of the metallic elements are sufficient to accommodate (with an appropriate safety factor) the loads for which they have been designed to withstand corrosion and adverse weather conditions.

PAINTS

For their anticorrosive protection, the metal parts are processed to release them, followed by a coating of polyzinc (zinc) and then electrostatic, two-layer polyester powder coating.

All production work processes for the processing of raw materials are carried out according to:

The ISO 9001: 2015 quality system

The ISO 14001: 2015 Environmental Management System