GOAL 0030-419

0030-419

TECHNICAL DESCRIPTION

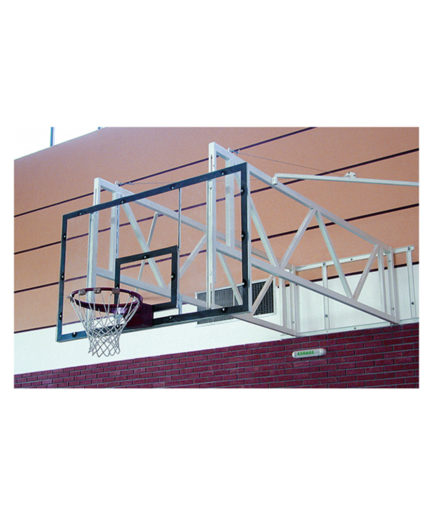

MOD. 0030 – 421

Each hob is made of three (3) aluminum beams.

The horizontal length 3,00 m and the two (2) vertical length 2,00 m. These beams are 80×80 mm square in shape and have ribs – reinforcements for greater strength. The edges of the square profile are curved.

The horizontal connection to the vertical beams has been fitted with an angular aluminum frame mounted appropriately and with three (3) corresponding milling screws galvanized per connection side. The whole construction is tasteful, rigid and stable.

On the back of the vertical beams there are appropriately shaped, hot-dipped tubes of open trapezoidal shape to fit the net. These tubes have a diameter of Ø 1 ″ and a thickness of 2 mm. The small, upper, parallel side is 600 mm long, the lower parallel side is 1000 mm long, and the length of the long side of the table is the height of the fireplace. The bottom corner of the table (on the floor) is sharp and not round, for better seating. They are connected to the hob with a specially designed hinge, of a suitable shape, dimension and cross-section, to allow folding, for easy storage and transportation of the hob. A Ø 1″ tube, 2 mm thick, thermally galvanized, is mounted horizontally, with a special connection, at the top and bottom of the table and connects its elements together to ensure better stability and uniform net support.

On the three (3) ground sides, rings (one on the small sides and two (2) on the large) are of suitable shape, cross-section and thickness to be mounted on the floor.

The entire construction ensures the stability of the hob on the floor.

Anchors of the appropriate shape and size are mounted on the back of the aluminum profile of the hob for firm and easy support of the nets. 8 to 10 anchors are provided for each vertical beam and 15 to 18 in the horizontal.

The net is placed at the back of the fireplace, loose so that the ball being thrown does not return to the stadium.

At the base of the two (2) vertical beams is placed a special rubber tap, corresponding to the profile, to protect the floor.

After the hob is fully connected and installed, its internal dimensions are 3.00×2.00 m.

The net is made entirely of plastic rope, with UV protection, 3 mm thick. The frame that forms the net is 10×10 cm.

The dimensions of the net are such that it is loosely positioned on the back of the hob and covers its entire area with the straps. The ball thrown into the net will not be returned to the field.

The beams are painted with electrostatic paint in white and red (RAL 3020) alternately at 200 mm intervals, as provided by the HANDBALL Federation.

METALLIC ELEMENTS

The metallic elements used in the manufacture of the equipment (screws, connectors, etc.) are made of metals either thermo-galvanized or electro-galvanized, where the surface preparation has been preceded by sandblasting or stainless steel. The dimensions and cross-sections of the metallic elements are sufficient to accommodate (with an appropriate safety factor) the loads for which they have been designed to withstand corrosion and adverse weather conditions.

PAINTS

The varnishes and paints that protect the wooden parts are specially designed for the climate of our country and are absolutely harmless to the users (they do not contain lead, chromium, cadmium or other heavy metals) and give high strength to our constructions.

For their anticorrosive protection, the metal parts are processed to release them, followed by a coating of polyzinc (zinc) and then electrostatic, two-layer polyester powder coating.

All production work processes for the processing of raw materials are carried out according to:

The ISO 9001: 2015 quality system

The ISO 14001: 2015 Environmental Management System