LIGHTING COLUMN 0020-327A

020-327A

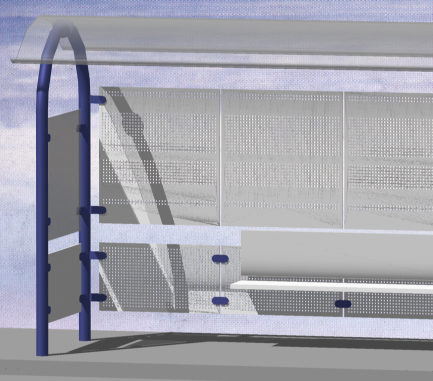

The SL1001 consists of the following parts:

The support base

The mast tissue

The light bulbs

The mounting base is a square flange measuring 35 x 35 cm and about 5 mm thick. At a distance of about 4 cm from the edges of the flange, four Ø 20 mm diameter holes are created to secure the lantern to the ground.

The lantern web is welded to the gasket, consisting of a pipe of 120 cm in length and Ø 4, in diameter, followed by another pipe of 130 cm in length και 2 ½ in diameter. In the joint of the two tubes is a metal piece of a traditional type joint. At the top of the web are two hanging lamps with the help of two fasteners.

Each hanging lamp is made up of a Ø 2’’ aluminum bracket that is fastened to its end with a 60 cm diameter aluminum tray. There is a special slot for the plastic lamp cover.

At the bottom of the lantern there is a detachable door that facilitates the connection of the current. Inside the lantern (base and web), a cable passes through the lamp.

The lamp is mounted to the ground either with plugs and screws or with anchors.

Lighting does not include electrical equipment.

METALLIC ELEMENTS

Metallic elements used in the manufacture of the equipment (screws, connectors, etc.) are made of metals either thermo-galvanized or electro-galvanized, where the surface preparation has been preceded by sandblasting or stainless steel. The dimensions and cross-sections of the metallic elements are sufficient to accommodate (with an appropriate safety factor) the loads for which they have been designed to withstand corrosion and adverse weather conditions.

PAINTS

For their anticorrosive protection, the metal parts are processed to release them, followed by a coating of polyzinc (zinc) and then electrostatic, two-layer polyester powder coating.

All production work processes for the processing of raw materials are carried out according to:

The ISO9001: 2015 quality system

The environmental management system ISO14001: 2015