LITTER BIN 20-05-10

20-05-10

TECHNICAL DESCRIPTION

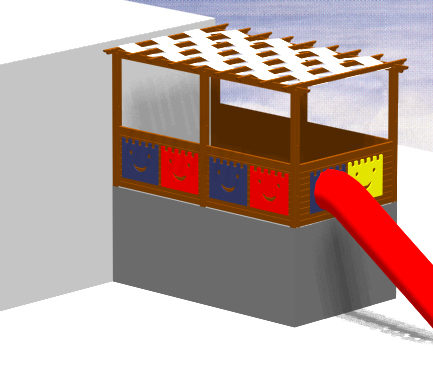

WOODEN BIN WITH METAL FRAME

Wooden bins with metal frame:

They are of high strength, suitable for safe and healthy disposal of light pedestrian trash. They are easy to use, functional and easy to clean. They are not easily destroyed and contribute to their upgrading of the environment. They are normally harmless, corrosion-resistant, acid-free and chemical-free. They are shaped like a frusto cone with an outer coating of wooden parts and are supported by a metal pole.

They have an internal bin of about 50 liters.

The wooden round bin bucket consists of three parts:

The main body

The metal inner bucket

and the support column

The main body of the bucket consists of two 30×3 mm cross-section steel blades which are shaped in a circular shape. The upper one has a diameter of 37.5 cm while the lower one has a diameter of 27.5 cm.

They are located in a distance 61 cm from each other. Their joining is done with two 30×3 mm cross bars and 61 cm long blades.

The wooden parts of the bucket are applied to the blades.

They consist of 14 pieces of Swedish timber, of 4.2x2cm and 75cm length.

The wood is applied with the help of 28 pieces of 1 / 4X35 screws in such a way as to cut 4 in and out of the blades.

The lower blade also has the mounting point of the inner bucket, which consists of two 30×3 mm cross bars and 27.5 cm long cross-shaped blades.

The inner metal bin is made of galvanized 0.8 mm thick, frusto cone shaped. Its base diameter is 26 cm, the diameter of the rim is 36 cm and 64 cm high, and on its rim there is a reinforcing perimeter metal cord and two facing handles to facilitate its discharge. It rests on the inside of the basket. The metal bucket has four escape holes at the bottom to drain rainwater and waste liquids into the bin.

The metal bin support column is made of a 60 mm cross-section tube and is 20 cm long.

At its base it has a support flange which is circular and has a diameter of 20 cm and a thickness of 5 mm.

METALLIC ELEMENTS

Metallic elements used in the manufacture of the equipment (screws, connectors, etc.) are made of metals either thermo-galvanized or electro-galvanized, where the surface preparation has been preceded by sandblasting or stainless steel. The dimensions and cross-sections of the metallic elements are sufficient to accommodate (with an appropriate safety factor) the loads for which they have been designed to withstand corrosion and adverse weather conditions.

PAINTS

The varnishes and paints that protect the wooden parts are specially designed for the climate of our country and are absolutely harmless to the users (they do not contain lead, chromium, cadmium or other heavy metals) and give high strength to our constructions.

For their anticorrosive protection, the metal parts are processed for polishing, followed by a coating of polyzinc (zinc) and then electrostatic, two-layer polyester powder coating.

All production work processes for the processing of raw materials are carried out according to:

The ISO 9001: 2015 quality system

The ISO 14001: 2015 Environmental Management System