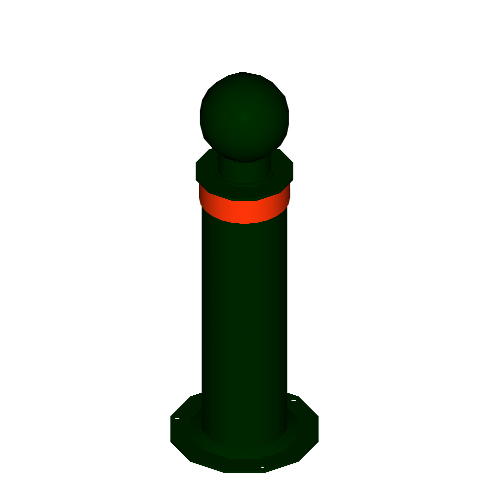

SIDEWALK BOLLARD 20-07-09

20-07-09

The column is 70 cm high. It consists of:

The metal base

The main body

The spherical upper

The base is made of metal flange Ø 25 cm in thickness 4mm. with three through holes 2 cm from the outside. Above it is the main body which consists of a metal pipe about Ø 4 ″ in cross section and 50 cm high.

At the top, place an aluminum ball Ø 15 cm with a built-in support at the bottom that fits into the main body.

The column may have a reflective film of 5.5 cm wide red or yellow. It is mounted on the ground by means of a mounting screw in the three through holes of the base.

METALLIC ELEMENTS

Metallic elements used in the manufacture of the equipment (screws, connectors, etc.) are made of metals either thermo-galvanized or electro-galvanized, where the surface preparation has been preceded by sandblasting or stainless steel. The dimensions and cross-sections of the metallic elements are sufficient to accommodate (with an appropriate safety factor) the loads for which they have been designed to withstand corrosion and adverse weather conditions.

PAINTS

For their anticorrosive protection, the metal parts are processed to release them, followed by a coating of polyzinc (zinc) and then electrostatic, two-layer polyester powder coating.

All production work processes for the processing of raw materials are carried out according to:

The ISO 9001: 2015 quality system

The environmental management system ISO14001: 2015