STEEL STRUCTURE 10-07-03

10-07-03

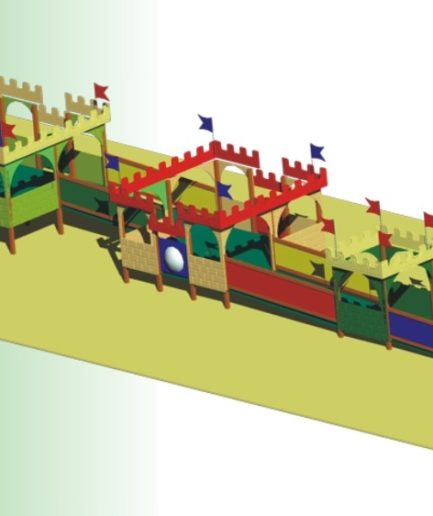

The composite metal instrument is 450x445cm and 373cm high and consists of:

2 pcs loft 122 cm high with arched lid

1 pcs staircase for loft height 122 cm

2 pairs of safety handles

2 pcs

1 pc mesh climbing

1 pcs bridge with security handrails

2 pcs open slides straight height 122 cm.

2 pcs slide protection hood

1 pcs panel – triple frame (below deck level)

1 pcs panel – frame transparent hollow circular “window” (above deck level)

1 pcs panel – smile frame (above deck level)

1 pc panel – Frame with numbers

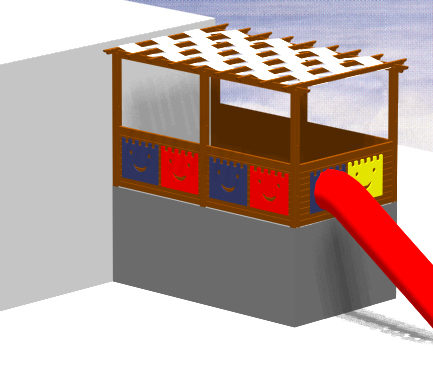

METALLIC LOFT 122 EC.

(with double arched cover with perforated sheet)

The loft 122 cm high has a total dimension of 111,5×111,5 cm and a height of 373 cm and consists of:

4 pcs circular beams Ø 90 mm with a thickness of 3 mm and height:

– A ‘306 cm (mounting with gaskets and metal plugs on safety floor) and

– B ‘402 cm (ground, safety belt according to EN 1177 standard with 30 cm sand).

Deck (102,5×102,5x8cm) made of 21 mm thick sliding wireness plywood in which all γ 90 mm circular apertures are created at the four corners to support the four circular beams. The deck carries a 60×40 mm cross-section heavy-duty steel cradle at the bottom, which gives it a robust construction.

METALLIC LADDER FOR LOFT HEIGHT 122 CM.

The climbing ladder consists of 4 steps of 6×2 cm oval and 52 cm long oval tubes, of stairs support made of 4x6cm cross-section, handrail and railings made of hot rolled laminate Ø ¾”.

The loft handrails are “P” shaped with rounded corners and are made of hot rolled laminate Ø1 “. In the meantime there are hot-rolled laminated railings Ø ½ ”.

SAFETY HANDLES

The safety handles are metallic electrostatic paint with vertical alignment in two, with the inner wrapped at the top. It has a metal blade at its bottom and a point at the top. They are made of a tube Ø 32 mm approximately 80 cm high and spaced apart according to EN 1176. After being degreased, they are coated with polyzinc (zinc) and then electrostatic powder coating.

The safety handles are fitted in places where there are no entry / exit protectors (panels, railings, etc.).

STRAIGHT CORRUGATED SLIDE 122 CM.

The straight corrugated slide is approximately 122 cm high and 235 cm in height from the loft.

It is manufactured by the rotary extraction method. It consists of linear low density polyethylene and with the addition of materials that provide protection from UV radiation and against static electricity.

Each color, which is non-toxic, is applied by rotary extraction of the mold. It is a one-piece and mounted with a one-piece Hood cover of the same material, for protection against falls

These materials are disciplined by:

ASTM– D – 790 (Flex Modulus – Flexible elements)

ASTM– D – 638 (Tensile Strength)

ASTM -D- 648 (Heat Distortion Temperature- Heated Distortion)

ARM– STD (Low Temperature Impact – low temperature resistance effect)

The side walls should have a diameter of at least 5 cm. Exceptions should be mentioned.

ASTM = the American Society for Testing and Materials, the American Materials Testing and Testing Service.

HOODS

The slide guard protects children from leaving their seats in order to avoid accidents. It is 105 cm high, 87 cm wide and 10 cm wide. about.

They are manufactured by the method of rotary extraction into molds. It consists of linear low density polyethylene and with the addition of materials that provide protection from UV radiation and against static electricity.

Each color, which is non-toxic, is applied by rotary extraction of the mold.

These materials are disciplined by:

ASTM– D – 790 (Flex Modulus – Flexible elements)

ASTM– D – 638 (Tensile Strength)

ASTM – D – 648 (Heat Distortion Temperature – Heated Distortion)

ARM– STD (Low Temperature Impact – low temperature resistance effect)

ASTM = the American Society for Testing and Materials, the American Materials Testing and Testing Service.

ARCHED COVER

The arch has dimensions of about 122x122x81 cm, and an inner height of 63 cm. The cover consists of two arches which are connected by a perforated sheet.

They are manufactured by the method of rotary extraction into molds. It is formed of linear low density polyethylene and with the addition of materials that provide protection from UV radiation and against static electricity.

Each color, which is non-toxic, is applied by rotary extraction of the mold. It’s a one-piece piece.

These materials are disciplined by:

ASTM– D – 790 (Flex Modulus – Flexible elements)

ASTM– D – 638 (Tensile Strength)

ASTM – D – 648 (Heat Distortion Temperature – Heated Distortion)

ARM– STD (Low Temperature Impact – low temperature resistance effect)

ASTM = the American Society for Testing and Materials, the American Materials Testing and Testing Service.

CLIMBING NET (for loft height 142 cm)

The climbing net consists of:

3 polypropylene (PP) coated ropes with a cross section of 16 mm and a length of 205 cm.

6 polypropylene (PP) tubular arms with 27 mm cross-sectional lengths of 42.5 cm.

3 M8 hot-dip galvanized joints.

3 hot-dip galvanized N6 keys.

1 metallic electrostatic paint holder with 3 fastening nuts on top and used for underground installation. It is made of “P” shape with a width of 42.5 cm and a height of 65 cm.

The three polypropylene coated ropes are connected to the 5 polypropylene tubular arms (steps) through their anvils and are positioned at intervals. The first step at a height of 40 cm from the ground surface and the rest with a gap of 23 cm between them. The upper ends of the three ropes are connected to the loft by the M10 connectors.

At their lower ends are the ropes with the metal base “P” through the nautical keys, which base is mounted in the ground with a hook.

The climbing net is applied to the side of the loft with two metal safety handles.

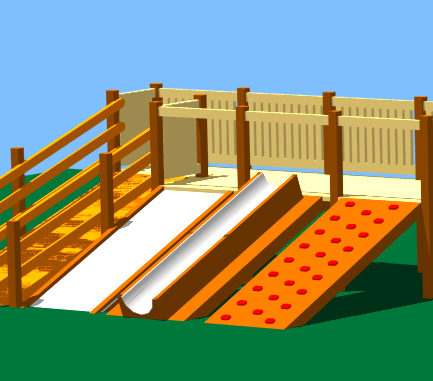

METALLIC BRIDGE WITH SECURITY RATES

The bridge consists of a deck of 102.5 cm wide, 200 cm long and 8 cm thick. The deck is made of hot rolled sheet steel 3 mm thick. At its four corners, Ø 90 mm circular apertures are created to accommodate the four circular beams.

The metal deck has a single, 80 mm, peripherally machined, pressed front. At the bottom of the deck there are supporting nerves. The deck surface is ει 8 mm punctured and laminated 3 mm thick.

The 191x96cm security railing is made of hot-rolled laminates. They are fitted with two horizontal plates Ø 1 ½ ”(50 mm) with welded brackets that are screwed onto the attic beams with M6 screws.

PROTECTIVE FRAMEWORK-PANEL

The protective frame is approximately 93,5X97X6 cm and consists of:

2 wooden columns approximately 4x6x97 cm.

1 plywood of colored birch approximately 85,5X90X2 cm.

Between the pillars is the birch plywood, approximately 85,5x90x2 cm, in which relief figures or themes can be carved.

The protective frame is located on the plane above the loft floor and is secured to the loft pillars.

THREE-PLY FRAME PANEL

The three-ply frame panel is 93X97.5 cm in size and consists of two tubes Ø ¾ long 93 cm horizontally above and below fitted with four vertical tubes Ø ¾”, two at each end.

In the intermediate void is carried three tubes Ø ¾ which hold three rows of three pieces of 13cm and Ø 8cm beech wood.

PANEL – FRAMEWORK

CIRCULAR “WINDOW”

The transparent “window” hollow circular panel frame is 93X97.5 cm in size and consists of two tubes Ø ¾ 93 cm long horizontally above and below the perforated sheet metal 92.7X93 cm, 2 mm thick, and with perforation Ø 8 mm. The sheet metal has a mechanical spin at its ends with a circular hole in the center. Inside the hole there is a transparent hollow plexi glass circular window.

PAINTED PLYWOOD BIRCH

The plywood elements required for our constructions are approximately 20 mm thick and are made of 1.5 mm thick laminated wood with pressurized heat sealant using non-toxic phenolic base resins. They are painted with water-soluble paints to which no seals, solvents or dyes containing lead, chromium, cadmium or other heavy metals have been attached. The colors are also very resistant to adverse weather conditions.

The above plywood sheets are in accordance with EN 314-2. The quality of the plywood is such that no further processing is required before painting, such as, for example, stocking, and reliefs and themes can be engraved.

PLASTIC INFORMATION

The plastic components required to manufacture the equipment are highly resistant to UV radiation and adverse weather conditions. Preferred are recyclable materials such as polyethylene (PE) or polypropylene (PP). Specifically all screws protruding from the equipment over 5 mm are covered with polypropylene (PP) plastic plugs. They are also safe for the safety and health of children.

METALLIC ELEMENTS

The metallic elements used in the manufacture of the equipment (screws, connectors, etc.) are made of metals either thermo-galvanized or electro-galvanized, where the surface preparation has been preceded by sandblasting or stainless steel. The dimensions and cross-sections of the metallic elements are sufficient to accommodate (with an appropriate safety factor) the loads for which they have been designed to withstand corrosion and adverse weather conditions.

PAINTS

The varnishes and the colors that protect the wooden parts are specially designed for the climate of our country (temperature changes, open or closed areas etc.) are completely harmless to the users (they do not contain lead, chromium, cadmium and other heavy metals). ) and give great durability to our constructions.

For their anticorrosive protection, the metal parts are processed to release them, followed by a coating of polyzinc (zinc) and then electrostatic, two-layer polyester powder coating.

PACKING

The following procedure is used for fixing the equipment:

At this point where the column is to be placed, an 80 cm deep pit is opened. about 60cm in diameter. Then, once the column is inserted, the pit is filled with frusto-concreted concrete until it reaches 10 cm. from the ground surface, where it is covered with soil.

Only ground irons, which hold each column at a distance of about 10 cm from the ground, are prevented on the ground in order to prevent the wood from corroding the soil moisture.

All production work processes for the processing of raw materials are carried out according to:

EN 1176 standards 1-6,

The ISO 9001: 2015 quality system

The environmental management system ISO14001: 2015