SWINGS 0010-255

0010-255

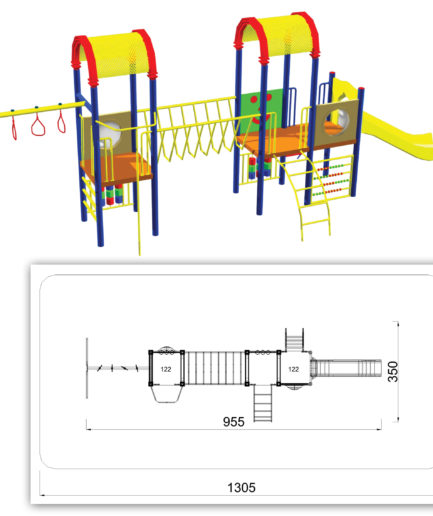

The two-seater metal swing has dimensions: 222 cm high and 312 cm long and consists of a central 2.5 ″ and 296 cm long hot-rolled laminate which is attached to each end by an 8 mm thick flange. four M12X35 mm screws with safety nuts (galvanized) per gasket.

The vertical elements of the swing are made of hot-rolled laminates of “L” shape 2’’ in height, 290 cm high and 180 cm in base.

The first swing of the swing starts at 64 cm from the edge of the horizontal plate. The next kitchen is 60 cm from the first. The distance between the swing seats is 48 cm.

The flat seat is of heavy construction type, is internally made of 345 MPa (91 mm) flat steel plate (50,000 psi) and has 8 mm diameter molded metal joints made of 304 stainless steel with 586 Mpa. 85,000 psi). The exterior of the seat is made of soft, comfortable black rubber.

They are slow ignition and provide high resistance to various chemicals. They are with UV stabilizers and provide antistatic protection.

For anti-rust protection, the crankcase is treated to achieve degreasing, followed by a coating of polyzinc (zinc) and then an electrostatic polyester powder paint.

PLASTIC INFORMATION

The plastic components required to manufacture the equipment are highly resistant to UV radiation and adverse weather conditions. Preferred are recyclable materials such as polyethylene (PE) or polypropylene (PP). Specifically all screws protruding from the equipment over 5 mm are covered with polypropylene (PP) plastic plugs. They are also safe for the safety and health of children.

METALLIC ELEMENTS

The metallic elements used in the manufacture of the equipment (screws, connectors, etc.) are made of metals either thermo-galvanized or electro-galvanized, where the surface preparation has been preceded by sandblasting or stainless steel. The dimensions and cross-sections of the metallic elements are sufficient to accommodate (with an appropriate safety factor) the loads for which they have been designed to withstand corrosion and adverse weather conditions.

PAINTS

For their anticorrosive protection, the metal parts are processed to release them, followed by a coating of polyzinc (zinc) and then electrostatic, two-layer polyester powder coating.

PACKING

The following procedure is used for fixing the equipment:

At this point where the column is to be placed, an 80 cm deep pit is opened. about 60cm in diameter. Then, once the column is inserted, the pit is filled with frusto-concreted concrete until it reaches 10 cm. from the ground surface, where it is covered with soil.

Only ground irons, which hold each column at a distance of about 10 cm from the ground, are prevented on the ground in order to prevent the wood from corroding the soil moisture.

All production work processes for the processing of raw materials are carried out according to:

EN 1176 standards 1-6,

The ISO9001: 2015 quality system

The environmental management system ISO14001: 2015