WOODEN STRUCTURE 10-09-02

The instrument consists of:

Loft 122 cm with a square lid

Loft 92 cm without cover

Staircase for loft 92 cm

92cm Straight Wave Slide (1 Pc)

122cm straight corrugated slide (1 pcs)

Semi-circular metal balcony

Protective Panels (2 pcs)

Safety plugs

Clamping Stands

The two lofts are joined by two common pillars. One of them has a square lid and the ascent is made of a wooden staircase that touches the loft without a lid of 92 cm. In the same loft there is a corrugated slide of 92 cm. The other slide is on the adjacent loft of 122 cm, on which it is also placed. the metal semi-circular balcony. Protective panels are mounted on two free sides.

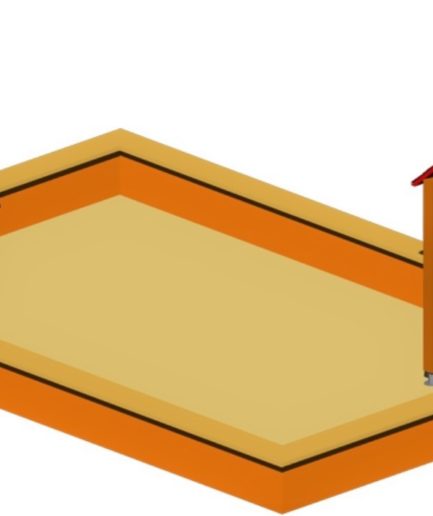

SQUARE WOODEN FLOOR h = 92 cm.

The 92 cm loft has a total dimension of 111,5X111,5X272 cm and consists of:

- 4 wooden pillars 9X9 cm and 272 cm high.

- 4 9x9x93,5 cm wood from which 4x4x93,5 cm length is removed.

- 1 Wireness Plywood, one side of which features a dark brown, non-slip floor. Its dimensions are 99X99 cm and its thickness is 21mm.

The loft floor is applied to the vertical wooden pillars 272 cm high and 92 cm high. The floor consists of 4 woods 9X9x93.5 cm, on which is supported the sliding (wireness) plywood that is the floor of the loft.

SQUARE WOODEN FLOOR h = 122 cm.

The loft 122 cm has a total dimension of 111,5X111,5X302 cm and consists of:

- 4 wooden pillars 9X9 cm and 272 cm high.

- 4 9x9x93.5cm wood from which 4x4x93.5cm length is removed.

- 1 Wireness Plywood, one side of which features a dark brown, non-slip floor. Its dimensions are 99X99 cm and its thickness is 21mm.

The loft floor is applied to the vertical wooden pillars 302 cm high and 122 cm high. The floor consists of 4 woods 9X9x93.5 cm, on which is supported the sliding (wireness) plywood that is the floor of the loft.

POLYETHYLENE SQUARE COVER

The square cover is approximately 122x122x70cm and has a hole-to-center dimension of 102.5cm on each side.

The cover is manufactured by the rotary extraction method molded. It is formed of linear low density polyethylene and with the addition of materials that provide protection from UV radiation and against static electricity.

Each color, which is non-toxic, is applied by rotary extraction of the mold.

SQUARE WOODEN FLOOR h = 122 cm.

The loft 122 cm has a total dimensions of 111,5X111,5X302 cm

WOODEN STAIRCASE FOR FLOOR 92 cm

The staircase for the height of 92 cm is 93X135 cm, the projection length of the lamp is approximately 94 cm and consists of:

- 2 wood 4.5,520×135 cm

- 4 wood 4,5x20x84,5 cm

- 4 wood 4,5x6x84,5 cm.

The 92cm staircase handrail consists of:

- 4 wood with curved edges 4,5x9x90 cm.

- 2 wood with curved edges 4,5x9x130 cm.

- 2 specially shaped rectangular birch plywood colored with internal angles of about 45 ° and 135 °, inscribed in a rectangular rectangle of approximately 110×200 cm, 2 cm thick.

Between the 2 x 20×135 cm timbers are placed the 4 x 4.5x6x84.5 cm x 20 cm timbers. On these 4 4,5Χ20Χ84,5 cm timbers are applied as presses.

The handrail is made as follows: The 2 woods 4.5x9x130 cm are facing each other and facing upwards. In these, they are screwed vertically 4,5x9x90 cm 2 by 2 on each side. Between the stairs of 20×135 cm, the sticks of 4,5x9x160 cm and the vertical sticks of 4.5x9x90 cm the rectangular gap on each side of the staircase is covered with birch plywood.

STRAIGHT CORRUGATED SLIDE HEIGHT 92 cm.

The straight corrugated slide has a height of 92 cm and a projection length of 185 cm. It is manufactured by the molding rotary extraction method. It is formed of linear low density polyethylene with UV stabilizers and provides antistatic (static electricity) protection.

Each color, which is non-toxic, is applied by rotary extraction of the mold. It is one-piece and also has a one-piece protective cover to prevent falls.

STRAIGHT CORRUGATED SLIDE HEIGHT 122 cm.

The straight corrugated slide has a height of about 122 cm and a projection length of 215 cm.Manufactured by the rotary extraction method. It consists of linear low density polyethylene and with the addition of materials that provide protection from UV radiation and against static electricity.Each color, which is non-toxic, is applied by rotary extraction of the mold. It is one-piece and mounted with a one-piece Hood cover of the same material, for protection against falls.

Hoods

The slide guard protects children from sitting in the seat to avoid accidents. It is 105 cm high, 87 cm wide and approximately 10 cm wide.They are manufactured by the method of rotary extraction into molds. It consists of linear low density polyethylene and with the addition of materials that provide protection from UV radiation and against static electricity.Each color, which is non-toxic, is applied by rotary extraction of the mold.

SEMI-CIRCUIT METAL BALCONY

It has a radius of 55.5 cm and consists of a metal deck (3 mm thick extruded sheet metal) with a single 80 mm single-sided peripherally machined press. At the bottom of the deck there are supporting nerves. The 96 cm height railing made of Ø 1 ¼ ”(50 mm) pipe and vertical elements Ø 1 (” (38 mm) welded together. They are screwed onto the beams by means of electro-galvanized M8 screws.

SECURITY PLUGS (small)

The safety caps are made of polypropylene (PP) with a base dimension of Ø37 mm and a height of 18 mm. They are designed to have a hole for the screw to pass through and cover the screw head with a fully fitted and secure lid.

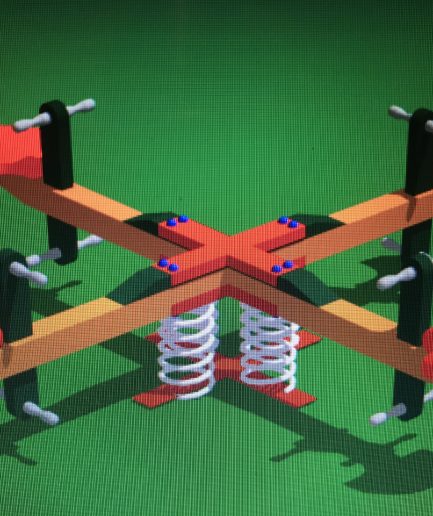

BACKPACK BASES

For fixing the instrument to the ground, each pair has a pair of mounting bases.

The mounting bases consist of two galvanized metal plates and then painted with electrostatic paint, of a shape “P” and approximately 100x12x4 cm thick and 0.5cm thick, which “hug” the column and are joined by passing screws 5 / 8 ″ X15. At the bottom there is a metal flange to hold them in the concrete pit.

Only ground irons, which hold the column at least 5 cm above the ground, are prevented from being ground in order to prevent the wood from being eroded by soil moisture.

TIMBER

The wood used for the equipment is Swedish pine wood composite laminate,. It is manufactured with special compound (welding of wood) in different sections depending on the intended use.

COMPOSITE wood is 40% stronger than full body wood. Contains about 15% moisture

It has antimagnetic properties and is a poor conductor of electricity.

COLORED PLYWOOD BIRCH

The plywood elements required for our constructions are approximately 18mm thick and are made of 1.5mm thick wood laminated with pressurized heat sealant using non-toxic phenolic base resins. They are painted with water-soluble paints to which no seals, thinners or paints containing lead, chromium, cadmium or other heavy metals have been attached. The colors are also very resistant to adverse weather conditions

PLASTIC ELEMENTS

The plastic components required to manufacture the equipment are highly resistant to UV radiation and adverse weather conditions. Preferred are recyclable materials such as polyethylene (PE) or polypropylene (PP). Specifically all screws protruding from the equipment over 5 mm are covered with polypropylene (PP) plastic plugs. They are also safe for the safety and health of children.

METALLIC ELEMENTS

The metallic elements used in the manufacture of the equipment (screws, joints, etc.) are made of metals either thermo-galvanized or electro-galvanized, where the surface preparation has been preceded by sandblasting or stainless steel. The dimensions and cross-sections of the metallic elements are sufficient to accommodate (with an appropriate safety factor) the loads for which they have been designed to withstand corrosion and adverse weather conditions. Painting of all metallic elements is done by the electrostatic paint method.

PAINTS

The varnishes and colors that protect the wooden parts are specially designed for the climate of our country (temperature changes, open or closed areas etc.) are completely harmless to the users (they do not contain lead, chromium, cadmium and other heavy metals) ) and give great strength to our constructions.

For their anticorrosive protection, the metal parts are processed for polishing, followed by a coating of polyzinc (zinc) and then electrostatic, two-layer polyester powder coating.

PACKING

The following procedure is used for fixing the equipment:

At this point where the column is to be installed, a pit about 80 cm deep and 60 cm in diameter is opened. Then, once the column has been inserted, the pit is filled with fractured cone-shaped concrete until it reaches 10 cm from the ground surface, where it is covered with soil.

Only ground irons, which hold each column at a distance of about 10 cm from the ground, are prevented on the ground in order to prevent the wood from being corroded by soil moisture.

All production work processes for the processing of raw materials are carried out according to:

- EN 1176 standards 1-6,

- ISO 9001: 2015 quality system

- The ISO 14001: 2015 environmental management system